Detecting

Using real-time anomaly detection algorithms to monitor a machine’s behavior while operating can provide valuable insights and help identify abnormal patterns or deviations from expected behavior.

Diagnosing

using artificial intelligence techniques or your expert’s knowledge by analyzing machine data to diagnose machine failures remotely. it gives you a deep insight into the problem before the first call from the customer side.

Predicting

Using artificial intelligence techniques to predict when the machine possibly needs maintenance to prevent unplanned downtime. it helps you to schedule your maintenance plan and prepare your maintenance team, tools, and spare parts.

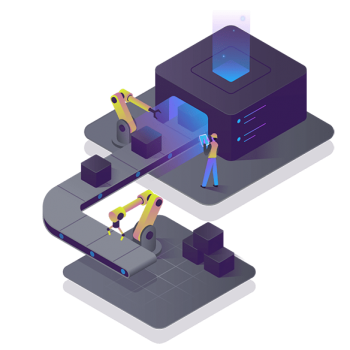

MONITOR REMOTELY, DELIVER GLOBALLY

World Wide

Coverage

Equipment manufacturers are strategically positioned to leverage machines’ data using AI and IoT tools.

STAY CLOSE TO YOUR PRODUCTS AFTER THE SALE.

- Installation Start-up

- Remote Assistance

- Machine Evaluation and Optimization

- Training Customers Technician

FROM COLLECTING DATA TO COLLECTIVE LEARNING

SMART SENSORS

Collect the data you need by attaching sensors to the body of your machines.

AI PROCESSING

Make a better decision by processing data with machine learning algorithms.

WIRELESS NETWORK

Using a WI-FI mesh network makes it possible for all your machines to be connected, securely and easily.

OUR PARTNERS AND CUSTOMERS

ventureLAB™ is a leading global founder community for hardware technology and enterprise software companies in Canada.

prediot is a member of ventureLAB.

LATEST POSTS FROM PREDIOT BLOG

Monitoring remotely and delivering globally

-

Posted by

hossein

- 0 comments

Prediot Mesh Networking

-

Posted by

- 0 comments

Why Wireless in Harsh Industrial Environments?

-

Posted by

- 0 comments

Predictive Maintenance and IoT

-

Posted by

- 0 comments

The future of manufacturing and role of data

-

Posted by

- 0 comments

OEMs Need New Business Models

-

Posted by

- 0 comments

Industrial Inventory Management

-

Posted by

- 0 comments

How Prediot can help the clean energy sector

-

Posted by

- 0 comments

Challenges in the aftermarket services

-

Posted by

- 0 comments

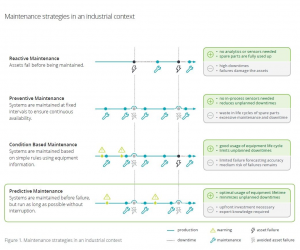

Maintenance Strategies on an Industrial Scale

-

Posted by

- 0 comments

Prediot main focus

-

Posted by

- 0 comments

How Prediot Help Spare Parts Suppliers?

-

Posted by

- 0 comments